If the dining room is the stage, the commercial kitchen is the high-performance engine that powers the entire restaurant. When that engine sputters – due to bottlenecks, wasted steps or cross-traffic chaos – the entire operation slows down. For any establishment focused on high-volume service, whether it’s a bustling fast-casual spot or a busy full-service restaurant, the layout of the back-of-house (BOH) isn’t just about aesthetics; it is the ultimate determinant of speed, consistency and profitability.

Optimizing a kitchen for speed isn’t about running faster; it’s about designing a space where unnecessary movement is eliminated. It’s about applying the principles of efficient industrial flow, often referred to as Lean Management, to the culinary world.

Let’s dive into how you can design or reconfigure your kitchen to be a well-oiled machine that handles peak service like a dream.

1. The Core Principle: A Linear Flow

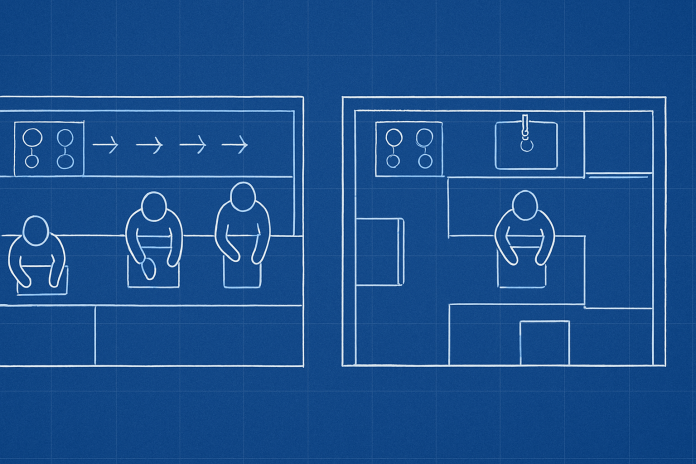

The single most crucial element of a high-speed kitchen is ensuring a logical, linear flow of products and personnel. This means ingredients should enter the kitchen area and move along a defined, one-way path from beginning to end without doubling back or crossing paths unnecessarily.

A perfect linear flow follows this sequence:

- Receiving & storage: Ingredients arrive and go immediately to dry storage, refrigeration or freezer units.

- Preparation (prep): Stored ingredients are moved to dedicated prep stations.

- Cooking (line): Prepped ingredients are moved to the cooking line (grills, ovens, fryers).

- Expediting & plating (the pass): Cooked food moves to the pass for final garnishing and pickup by the Front-of-House (FOH) staff.

- Service: Food leaves the kitchen.

- Warewashing: Dirty dishes return to a dedicated, isolated area for cleaning, without crossing into the food prep or cooking zones.

When this flow is strictly maintained, you eliminate the “motion” waste (excessive walking) and “waiting” waste (bottlenecks) that plague inefficient kitchens, especially during a rush.

2. Choosing Your Ideal Layout: Assembly Line vs. Zone Style

While many kitchen designs exist, two are fundamentally engineered for high volume and speed:

A. The assembly line layout (The QSR champion)

This layout is the speed demon of the restaurant world, perfect for quick-service restaurants (QSRs), sandwich shops or any operation with a limited, repetitive menu.

- How it works: All equipment is arranged in a straight line or in a tight U-shape. Each station performs one specific, simple task sequentially, much like a classic factory assembly line. Think of a burrito or pizza station where the cook slides the product down the line, adding ingredients at each step until it’s finished at the end.

- Speed advantage: It drastically reduces complex decision-making and cross-traffic. The cook never leaves their station and the flow of the dish is continuous and highly predictable.

B. The zone-style layout (The flexible powerhouse)

This style is better suited for full-service restaurants with diverse menus requiring multiple cooking methods (e.g., separate sauté, grill, fryer and cold-prep sections).

- How it works: The kitchen is divided into distinct, self-contained zones based on the task. The grill zone has all its necessary tools and refrigerated drawers; the pastry zone is isolated with its own prep area etc. The center of the kitchen is usually a wide, clear aisle that acts as the artery connecting these zones.

- Speed advantage: It allows multiple teams to work simultaneously without interfering with one another. If the sauté station is slammed, it doesn’t slow down the cold prep (salads, appetizers), keeping the overall ticket time manageable.

3. The Details: Micro-Optimization for Productivity

Once the macro-layout is chosen, efficiency lives in the details of each workstation.

The magic of the “kitchen triangle”

Adapting the classic residential kitchen triangle (stove, sink, fridge) for a commercial setting is vital. For every specific cooking station (e.g., the grill station), ensure the three core elements are within a single step’s reach:

- Cooking surface: The grill or range.

- Prep sink/handwash station: Essential for immediate cleaning and safety compliance.

- Mise en place storage: Refrigerated drawers or countertop containers holding all frequently used ingredients.

If a cook has to take more than two steps to grab the tongs, reach the cutting board or get a main ingredient, the station is inefficient.

The strategic placement of tech: KDS and POS

Technology should reinforce, not disrupt, the physical flow. A kitchen display system (KDS) needs to be mounted exactly where the expeditor can manage the pass and where the cooks can clearly see their designated tickets without breaking their rhythm.

For the FOH-to-BOH transition, the distance between the POS terminals and the expedite station should be minimal to allow servers to efficiently drop off dirty plates and pick up new orders, limiting their time spent in the kitchen and reducing collision risk. A common practice is to have the dish return area strategically positioned near the back service entrance for servers but far away from the food prep line.

Isolating the warewashing zone

This is often overlooked but critical for flow. The dishwashing area must be a dead-end zone. Dirty plates coming in should never pass through the path where clean food is exiting. By isolating this area, you eliminate the risk of cross-contamination and prevent servers carrying stacks of dirty dishes from bumping into chefs carrying finished plates. Learning how to strategically zone your kitchen for maximum efficiency is a game-changer.

4. Designing for Comfort and Safety (The Ergonomics of Speed)

A high-speed kitchen is also a high-stress environment, and fatigue slows everyone down. Design choices that promote ergonomics translate directly into sustained speed.

- Adjustable surfaces: Allowing staff to adjust counter height to match their tasks (slicing vs. standing at a grill) can reduce strain and improve precision.

- Anti-fatigue mats: These are non-negotiable on the line. They absorb shock and reduce the strain on the feet and back of cooks who stand for eight to twelve hours, helping them stay energized and focused.

- Visibility: An open kitchen concept – or at least an open line – allows the Executive Chef or expeditor to supervise all stations instantly, catching errors before they become “defects” (wasted food). This ease of supervision improves team responsiveness.

In the end, designing a high-volume kitchen comes down to relentless efficiency and continuous improvement. By viewing your kitchen through the lens of maximizing flow and eliminating waste, you can turn a space that once saw frustrating bottlenecks into a high-octane production line that delights customers with consistent speed. The power of applying Lean Management principles to your restaurant goes beyond the kitchen and into your inventory and overall operations. It’s the smart way to move more meals and make more money.