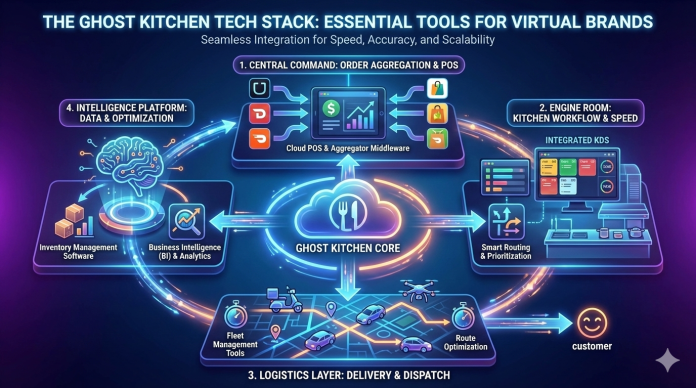

The ghost kitchen, or cloud kitchen, has fundamentally redefined the modern restaurant landscape. By eliminating the high overhead of a storefront and dining room, these virtual brands prioritize kitchen efficiency and logistics above all else. This shift has placed an unprecedented reliance on technology. In this delivery-first model, the technology stack is not merely a support function—it is the core operational infrastructure that determines profitability, consistency and scalability.

To thrive in the competitive virtual landscape, operators must move beyond a patchwork of disparate tablets and embrace a unified, intelligent tech stack. This comprehensive system is built upon four essential pillars, each designed to optimize a specific stage of the order fulfillment workflow.

1. The Central Command: Order Aggregation and POS

The immediate challenge for any virtual brand operating across multiple platforms (Uber Eats, DoorDash, proprietary apps) is the chaos of ‘tablet hell.’ The solution is a robust, integrated order management system that serves as the central command.

Order aggregator/middleware platform

The order aggregator is the non-negotiable first layer of the tech stack. Its function is to pull all incoming orders from various third-party delivery platforms (3PDs) and first-party ordering channels into a single, unified feed.

- Eliminates manual entry: By automating the order intake, the system eradicates the most common cause of error: human re-entry of ticket details from a tablet into a Point-of-Sale (POS) system.

- Centralized menu management: Advanced aggregators allow operators to manage and update menus, pricing and item availability across all connected platforms simultaneously from one dashboard. This ensures brand consistency and operational coherence across all channels.

Cloud-based point-of-sale (POS) system

The POS acts as the system of record and the financial backbone of the operation. In the ghost kitchen model, it must be inherently cloud-native and API-driven to handle high-volume, digital-only transactions.

- Multi-brand accounting: The POS must accurately track sales, profit and costs segregated by individual virtual brand and by ordering channel. This data is critical for understanding which concepts are profitable and which platforms are performing.

- Inventory integration: The sales data flows directly into the inventory system, providing real-time deduction of ingredients—a crucial feature for minimizing the food waste inherent in a high-volume, dynamic environment.

2. The Engine Room: Kitchen Workflow and Speed

Once an order is accepted by the POS, the next critical phase is ensuring rapid and accurate preparation. This is where the Kitchen Display System (KDS) is paramount.

Integrated kitchen display system (KDS)

The KDS replaces paper tickets with digital screens on the kitchen line. This digital interface is essential for maintaining a high-throughput, error-free production line.

- Intelligent routing: A sophisticated KDS automatically routes specific items on a multi-dish ticket to the correct prep station (e.g., salads to cold prep, burgers to the grill). This eliminates confusion and streamlines the workflow.

- Real-time prioritization: The system manages cook times and promise times, displaying orders with color-coded urgency and enabling automatic ticket ‘bumping.’ This ensures staff are always working on the item that needs to be finished now for on-time delivery.

- Expediting and handoff: A dedicated expediter screen (the “Pass Screen”) allows staff to consolidate and check completed orders before the handoff, ensuring every bag is sealed with 100% accuracy. The seamless integration between the POS and KDS is foundational to reducing service speed and error rates in a production-focused kitchen.

3. The Logistics Layer: Delivery and Dispatch Management

With food prepared, the ghost kitchen’s final operational hurdle is the seamless handoff to the courier fleet, whether third-party or in-house.

Delivery optimization/fleet management tools

For operators running their own delivery fleet or a hybrid model, technology must optimize the final mile.

- Courier management: This software coordinates with 3PD APIs to notify kitchens of estimated courier arrival times, ensuring the food is ready for pickup just in time, minimizing the time a finished order sits under a heat lamp.

- Route optimization (in-house): For owned fleets, the system provides drivers with the most efficient route planning based on real-time traffic data, improving delivery speed and cutting down on fuel/labor costs.

4. The Intelligence Platform: Data and Optimization

The most advanced layer of the ghost kitchen tech stack transforms raw transaction data into actionable business intelligence.

Inventory management software

In a model built on low overhead and high-volume, controlling food cost is everything. An automated inventory system is crucial for margin protection.

- Real-time usage tracking: By linking to the POS and sales data, the system monitors ingredient usage, flags variances (food waste or theft) and calculates actual food cost per menu item.

- Demand forecasting: Modern inventory software utilizes sales data to accurately forecast future ingredient needs, allowing for Just-in-Time (JIT) ordering. This minimizes the holding cost and spoilage risk of perishable items.

Business intelligence (BI) and analytics

Ghost kitchens lack direct customer interaction, making data the sole source of market intelligence.

- Performance metrics: BI dashboards aggregate key metrics by brand, item and hour: average preparation time, delivery channel commission analysis, most profitable items and most common order errors.

- Menu engineering: Analyzing customer order patterns and sales data allows operators to make data-driven decisions on menu rotation, pricing adjustments and the precise dishes to include for new virtual brand concepts. Leveraging data analytics to predict demand and personalize marketing is a key differentiator in the ghost kitchen model.

Conclusion

The ghost kitchen is inherently a technology company that sells food. The sophistication of its tech stack dictates its competitive advantage. The convergence of cloud POS, order aggregation, KDS and automated inventory management forms a closed-loop system designed for one purpose: to process a high volume of digital orders with minimal waste, maximum speed and perfect consistency. For any virtual brand looking to scale effectively, investment in a unified, professional-grade tech stack is not an expense—it is the foundational capital expenditure for future growth.